Manually programming using print dimensions, enter full radius (or diameter depending.) and let the machine control calulate the cutter centerline.Ģ. Lathes are a different story and I would agree with you had this been a lathe issue. There are two methods for using "cutter compensation" (radius or diameter based on parameter settings in the control). I truly appreciate knowledgeable people that share their wealth on forums like this. Kind of frustrating, he's a my way or the highway kind of guy and needs to cause a scene to get a point across. Can anyone help explain to me what most likely happened in my situation and if i should change my post to how he wants it (where he enters an offset for all contour features which equals the radius of the cutter he is using)? Or if I should continue creating the post with a cutter in mind in which he then could calculate an offset if he wanted to use a different radius cutter? Anyway, make a long story short this technician has a history of having a "hot head" which makes him difficult to work with. He got all excited and told me that, that defeats the purpose of using a Tool Radius offset if he can't just enter in the radius of the cutter that he is using. Therefore I told him that if he specified a zero offset the part should machine to spec. In inspection I noticed that he had entered in the radius of the cutter as the offset for the contour milling block. After running the code he stormed in all fired up telling me that the size of the pocket was off by the radius of the cutter.

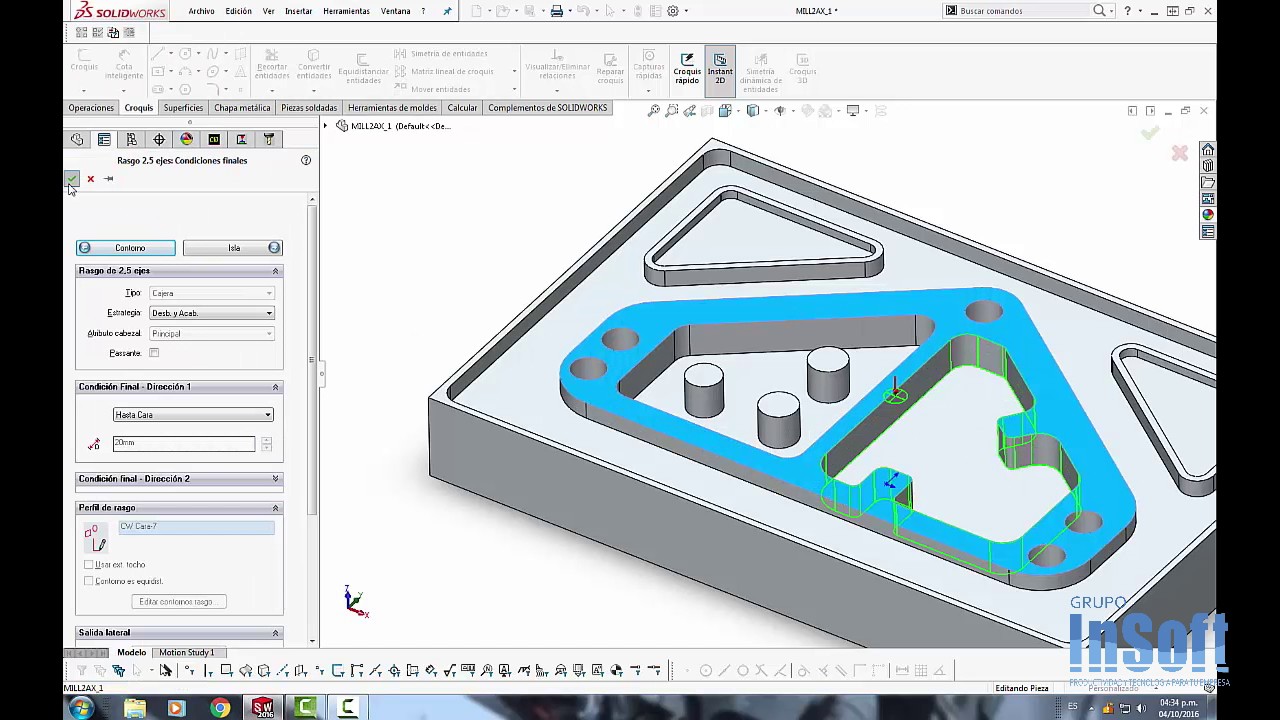

The technician that runs our VMC (an experienced manual machinist but somewhat new to CNC) had came in and asked me if I used a tool radius offset compensation on the contour in which i said yes. A 3/16" 4 flute End Mill was used for generating the code.

I created a program that used a contour milling cycle in finishing a pocket.

0 kommentar(er)

0 kommentar(er)